Countertop Bridge Saw

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Zhejiang

-

Validity to:

Long-term effective

-

Last update:

2023-10-02 16:31

-

Browse the number:

351

+

- Contactaixin:

hengxingjixie(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Zhejiang

Address:Hushan North Road, Xiaozhi Town, Linhai, Taizhou, Zhejiang, China

-

Website:

http://www.zlstonemachine.com/ http://hengxingjixie.taihuazhiyao.com/

+

Model | 4+1 Axis CNC bridge saw | 5+1 Axis CNC bridge saw | Unit |

Worktable size | L3500*W2000 | L3500*W2000 | mm |

Maximum cutting | L3500*W2000*H90 | L3500*W2000*H90 | mm |

Maximum chamfering | L3500*W2000*H60 | L3500*W2000*H60 | mm |

Blade diameter | 350-425 | 350-425 | mm |

Main motor power | 15 | 22 (permanet magnet motor with frequency) | kw |

Router power | 5.5 | 5.5 | kw |

Control center | industry computer with CNC | industry computer with CNC | Â |

Controller brand | own CNC system | own CNC system or ESA system from Italy |  |

Driving motor | Servo motor | Servo motor | Â |

Router max speed | 24000 | 24000 | RPM |

Total power | 28 | 35 | kw |

Suction cup lifting weight | 200 | 200 | kg |

Head rotate | 0°-360° | 0°-360° |  |

Head tilt | 0°and 45° | 0°-90° |  |

Cylinders | 5 | 5 | group |

Dimensions | L5750*W3260*H3800 | L5750*W3260*H3800 | mm |

Water consumption | 2 | 2 | m³/h |

Total weight | 5.4 | 5.4 | t |

Main part delivered size | 5750x2200x2500 | 5750x2200x2500 | mm |

Machine-delivered method | Main part delivered as a whole (HQÂ container) | Main part delivered as a whole (HQÂ container) | Â |

Price

Model | Own system (USD) | Option: ESA System | Option: Hot Galvanized (USD) | Option: front sliding doors | Option:worktable with plastic plate and rubber |

ZLBS-425CNC/5A | 31000 | +5000 | +2000 | +2000 | +1000 |

ZLBS-425CNC/4+1A | 26000 | Â | +2000 | +2000 | +1000 |

Feature

Â

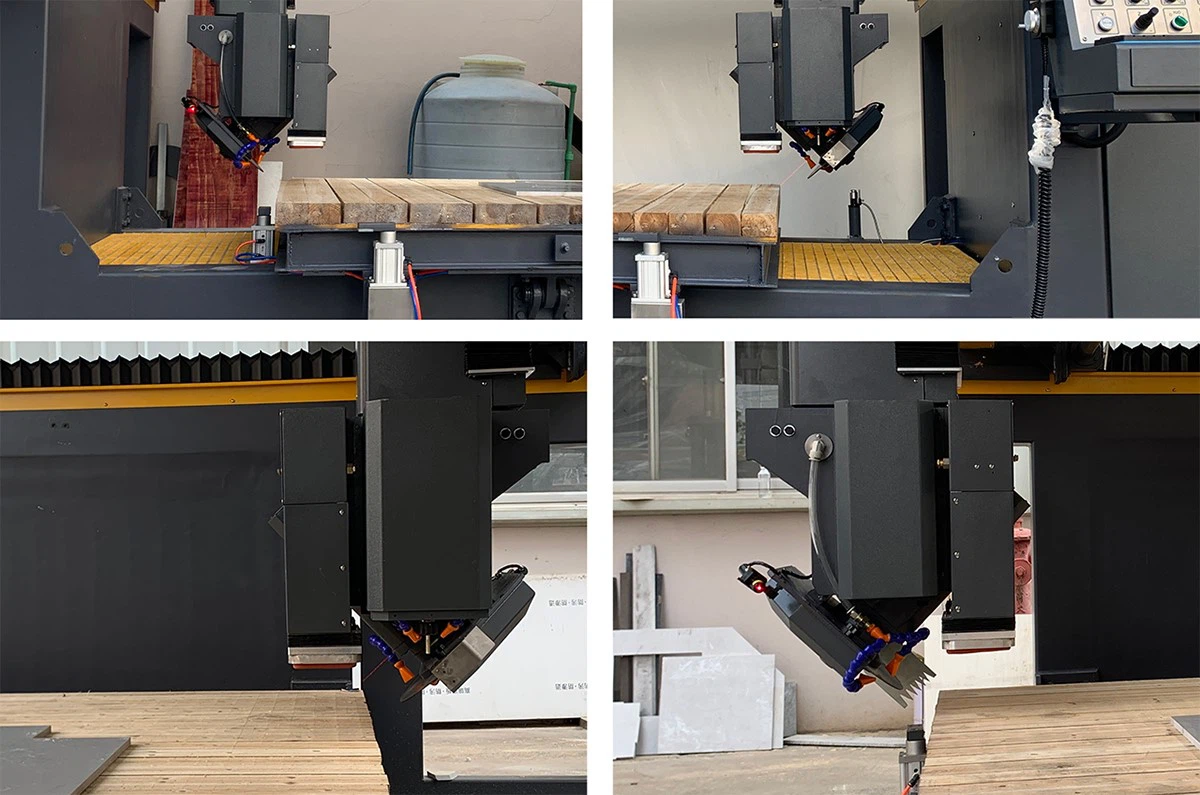

1: The machine is a conjoined structure; it takes up less space and is easy to install and move.

Â

2: This machine has excellent four-side chamfering function and an excellent chamfering range 3500x2000mm

Â

Â

​3: With an industrial computer and a 17" color touch-screen.

Â

Â

Option: own CNC system or ESA system from Italy

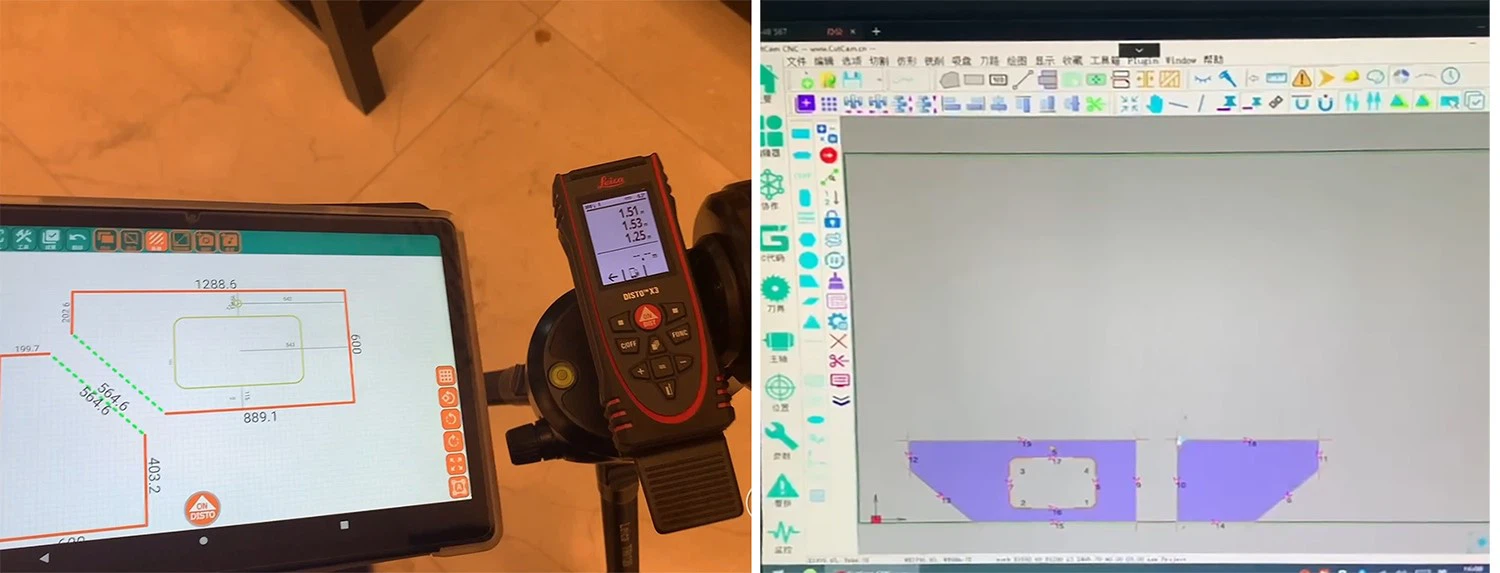

4: Use a camera to locate the position of the plate and display it in the cutting procedure.

Â

5: The (5+1)A type with a 22-KW permanent magnet motor can be cut along with the thickness of the cutting plate, automatically adjusting the output power, strength, and power-saving environmental protection.

6: An automatic tool setting gauge is equipped that automatically checks the blade.

Â

7. The system has a built-in library of conventional-shaped drawings and also supports DXF format imports from a designer or a countertop measuring gauge.

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

8: The worktable can be flipped up to 85°.

9: A group of rotating cylinders on the side of the work table will automatically press the plate when the milling cutter works and automatically withdraw after the milling cutter works.

Â

Â

10: Option: the machine chassis could be hot-dip galvanized, and the worktable could be faced with plastic plates and rubber.

Â

Â

11: Option: front sliding door

Â

Application Picture and Video

Â

Â

Â

Â

Â

Â

Â

Shipment

Factory

Â

Â

Honour

The operator begins processing after taking a picture of the plate and adding the drawing layout to the image. Saw blades, milling cutters, suction cups, and pressure plate cylinders will automatically generate combined processing steps according to the program.There are four groups of cylinders in front of the workbench. Before the milling cutter works, the program will automatically control the cylinder to press the plate. When the milling cutter is over, the cylinder will automatically drop, which is convenient for saw cutting.If the blade-cutting path conflicts, the suction cup can help.Additionally, conventional cross and straight slices of plates, various polygons, circles, ovals, and maws, as well as L-shaped countertops and four-sided under-hung countertops, are all cut and chamfer using the countertop bridge saw. The basin, faucet, and milling inner angles can all be processed by the miller. It is strong and appropriate for processing plates made of marble, quartz, granite, ceramic, sintered stone, and other materials. The machine can download the measuring instrument file, set the drawing, and then process it. Therefore, the machine is used to install countertops without using any dust. For the countertop industry, it is the best option.We also provide OEM/ODM production machine service; feel free to contact us.

Â

A countertop bridge saw is an essential tool for any professional or DIY enthusiast who wants to install kitchen or bathroom countertops. This fantastic piece of equipment offers many advantages, making it the go-to solution for cutting granite, marble, and other stone materials.

One of the main benefits of using a countertop bridge saw is its accuracy and precision. This tool is designed to deliver a clean, straight cut every time, ensuring that each cut is perfect and fits the exact measurements you need. This ensures that your countertops fit perfectly and look stunning in your home.

Another advantage of using a countertop bridge saw is its speed and efficiency. The advanced technology used in these saws ensures that each cut is quick and effortless. This saves time and reduces the risk of errors, making it possible to finish the project much faster than without one.

Additionally, using a countertop bridge saw is incredibly safe and user-friendly. It comes with all necessary safety features and precautions in place, reducing the risk of accidents or injuries. Furthermore, it is easy to use, even for beginners, making it accessible to anyone who wants to install their countertops.

Lastly, using a countertop bridge saw is cost-effective and saves you money in the long run. By cutting down on labor costs, you can do the work yourself and only pay for the equipment you hire or purchase. Plus, it is incredibly durable and long-lasting, providing you with many years of use and value for your investment.

In conclusion, a countertop bridge saw is a fantastic tool for anyone looking to install kitchen or bathroom countertops. Its accuracy and precision, speed and efficiency, safety features, ease of use, and cost-effectiveness make it a must-have for any DIY enthusiast or professional. So, if you're planning a countertop installation, this is a tool that should be at the top of your list.

http://www.zlstonemachine.com/